Synchronous Rotors

Due to their high power density and small design, synchronous rotors can reach very high torques.

They have a rotor with excellent dynamic properties to cope with such high torques. e+a synchronous rotors are also highly efficient.

With permanent magnet and CFRP sleeve (tapered sleeve system)

e+a permanent magnet rotors with carbon-fibre reinforced plastic (CFRP) sleeve provide a very rigid drive train made up of shaft and rotor.

With permanent magnet and CFRP sleeve (tapered sleeve system)

With permanent magnet and CFRP sleeve (direct assembly)

With the direct assembly method, the magnets and the CFRP sleeve are fitted directly to the customer-supplied shaft. This allows for a bigger shaft diameter compared to the tapered sleeve system.

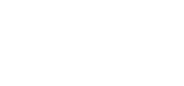

With permanent magnet and steel sleeve

Depending on the environmental conditions the motors are exposed to, sleeves made from special ferrous alloys can be used for increasing the durability of the rotors.

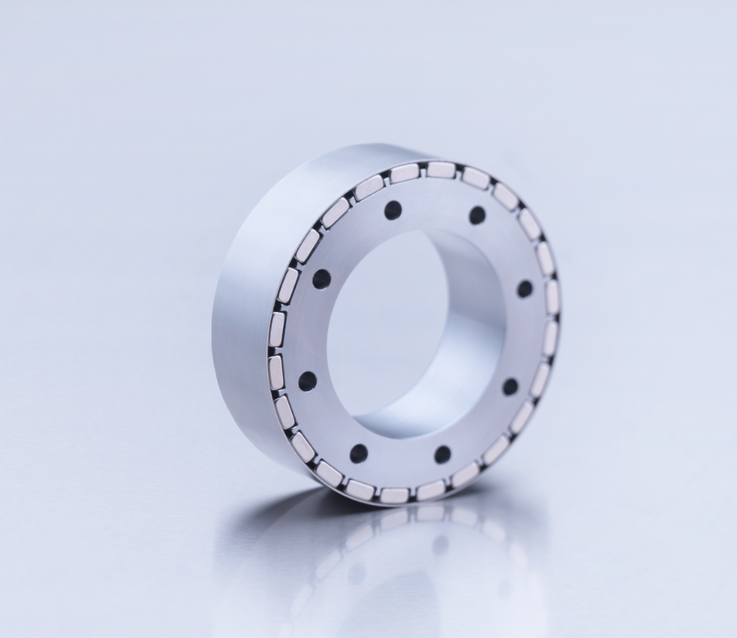

IPM - With Interior Magnets

e+a synchronous motors with interior magnet rotor design do enable high torque capability at low rotor temperature.

Torque motor with metallic sleeve

e+a torque motors come with a metallic sleeve to improve their durability and reliability.